LITHIUM IS THE FUTURE OF ELECTRIC GSE

ADVANTAGE OF LITHIUM TECHNOLOGY

Organizations throughout the aviation industry have relied on internal combustion engines to power their ground support equipment (GSE) for many decades. However, focus is shifting toward sustainability and reducing carbon emissions and many organizations are opting for electric GSE fleets powered by emission-free lithium batteries.

Lithium batteries offer a number of benefits that make it a superior choice over internal combustion and lead acid battery powered equipment. These benefits help improve safety, heighten performance, reduce downtime, costs, and provide a hassle-free user experience.

Benefits of Lithium Batteries Include:

- Low Cost of Operation

- No Battery Maintenance

- Superior Energy Efficiency

- Charges twice as fast compared to lead acid

- Opportunity Charging

- Consistent Performance

- Compatible with EV Charging Stations

- Eco-Friendly – Zero Emissions

SUPERIOR PERFORMANCE

LITHIUM TECHNOLOGY VS. GAS/DIESEL

In addition to a reduction in carbon emissions resulting from not burning diesel or gas, lithium-powered GSE doesn’t require changing of powertrain fluids – there’s no need for coolant, gas or oil changes. Unlike GSE powered by internal combustion engines, electric lithium GSE features eco-mode settings allowing the ability to idle using minimal power, working to maintain cabin temperature for the driver which is especially important in the cold. If your industry demands frequent starts and stops, electric lithium GSE also are not strained during start-ups like internal combustion engines.

Compared to gas and diesel powered GSE, lithium-powered GSE provides a significant reduction in noise. This reduction is another way lithium protects the safety of operators in all environments. Finally, with opportunity charging lithium-ion powered GSE can be charged right at the gate during downtime to recover what’s used during aircraft turns and other operations – eliminating the need for GSE fuel tanks to be refueled.

LITHIUM TECHNOLOGY VS. LEAD ACID

Within the range of battery-powered GSE, both lithium and lead acid batteries are options. While both are electric and offer several benefits over internal combustion engines, lithium and lead acid batteries are not on equal footing. Simply put, lithium is the future of energy technology.

Because more energy can be stored in a lithium-ion battery compared to a lead acid battery, using the same physical space, lithium batteries are significantly lighter. This is an important consideration for shipping and transportation. Lithium batteries also require no maintenance – eliminating watering and terminal cleaning which are necessary for lead acid batteries. Unlike lead acid batteries, lithium batteries can be opportunity charged without comprising the performance of the battery. This means vehicles can receive additional charges between aircraft if needed. A highly efficient power source, lithium batteries increase productivity by charging twice as fast than lead acid batteries.

BENEFITS OF LITHIUM TECHNOLOGY

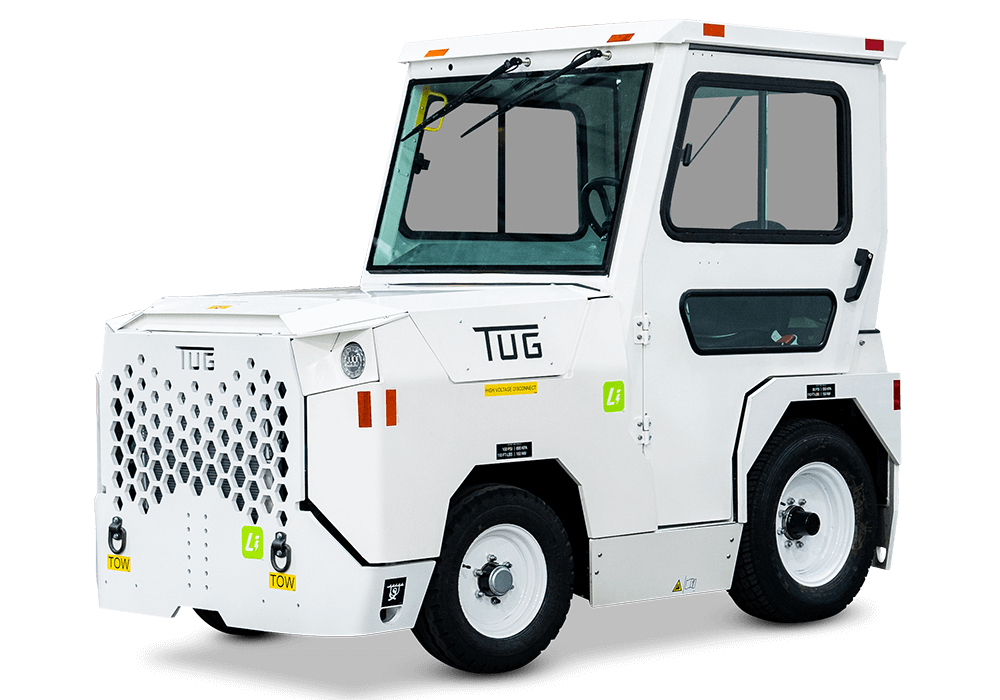

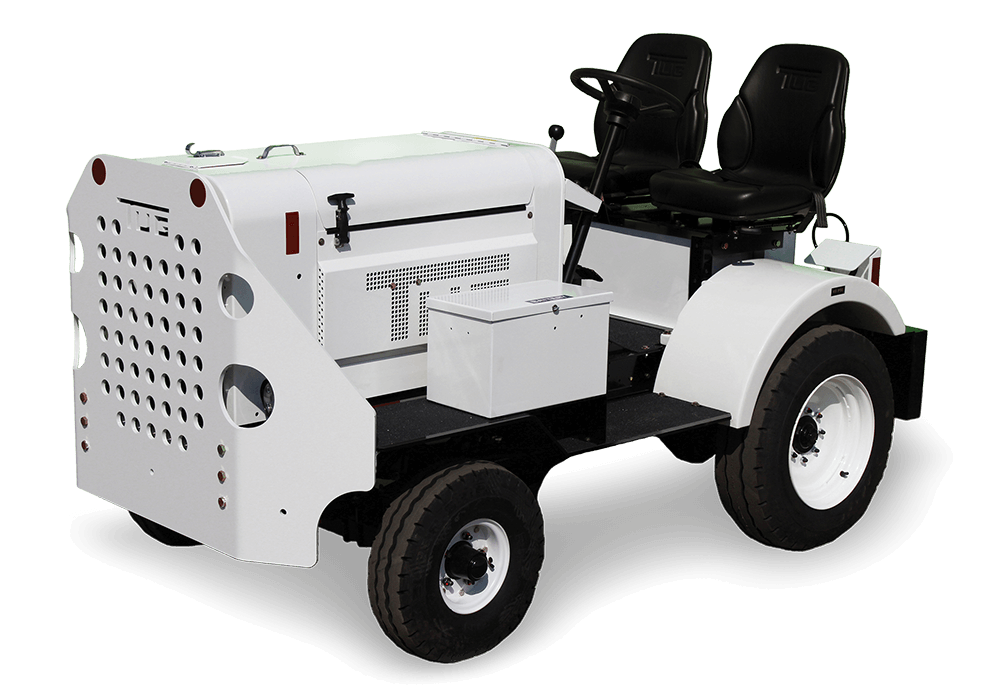

Textron GSE serves the airline industry with lithium powered equipment including a narrow-body aircraft pushback with the TUG ALPHA 1 and the TUG 660 belt-loader. These vehicles deliver lower cost of ownership, require zero battery maintenance and generate superior energy efficiency.

SAFE LITHIUM TECHNOLOGY

The TUG ALPHA 1 fits more power in a smaller space and provides faster-charging than traditional lead acid batteries. The TUG ALPHA 1 is equipped with a Battery Management System (BMS) utilizing a telemetry system, that monitors the health and performance of the battery. Although unlikely, if a fault occurs within the battery, the BMS system is designed to disable the vehicle, delivering enhanced safety. The NMC battery is fully enclosed in a steel box with a fire blanket around the pack for extra protection and safety.

IMPROVED SERVICEABILITY

Textron GSE’s lithium-powered TUG ALPHA 1 offers access to all maintenance points from the ground. With hassle-free maintenance checks, the TUG ALPHA 1 is not only a safer GSE option, it is more likely to be properly maintained which helps to prevent downtime and delays. The lithium battery utilized in the TUG ALPHA does not require watering or terminal cleaning, which results in shorter maintenance times and increased productivity.

OEM PARTS AND SERVICE

The Textron GSE Customer Service team is positioned to service your equipment including the TUG ALPHA 1 lithium model with OEM parts, specifically designed and tested for Textron GSE products. OEM parts further improve the safety and performance of our lithium-powered pushbacks. These parts are backed by leading reputations in the industry for excellent quality and expertise.

REPOWER & RETROFIT

In addition to the lithium model TUG ALPHA 1, Textron GSE also offers gas and diesel models that have been designed for future electric drivetrain upgrades. If you’re not ready to make the switch to a lithium-powered GSE unit, the TUG ALPHA 1 offers a variety of models to meet your needs.

UPGRADE YOUR OPERATIONS WITH LITHIUM TECHNOLOGY

Ready to experience the benefits of electrifying your fleet with lithium-powered GSE? Whether you’re a purchasing agent, engineer, or part of an environmental team, Textron GSE is ready to partner with you to help you find the solutions that will best serve your organization. With unparalleled safety features, simplified maintenance and a 5-year battery warranty, Textron GSE brings lithium technology to a new level. Contact us today with any questions or to get started.